A neodymium magnetic material is the second most commonly utilized kind of rare earth metal. It has excellent electrical and magnetic properties, and a wide range of uses in a variety of industries. It is extensively utilized for precision machining, coatings, soldering, forging, drilling, soldering, forging, and fastening, as well as for forming metal parts. It has unique electrochemical, mechanical, optical, and thermal properties, making it an excellent choice for a variety of applications. This material is frequently used as an insulator and has excellent thermal and chemical resistance.

The NdFeB magnet manufacturing process and the materials that are used in the process have some unique physical and electrical properties. NdFeB magnets have excellent electrical and magnetic properties. Because of its excellent electrical and magnetic properties, this material is known as NdFeB magnetic metal, and it is commonly used as an insulator for delicate electrical components, such as motor brushes, within a variety of applications.

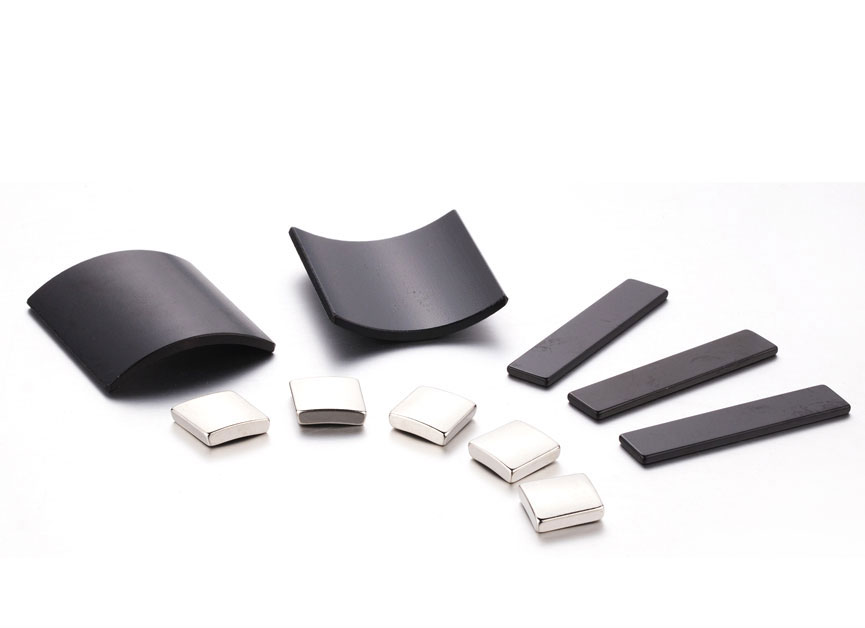

NdFeB magnets are formed by welding two pieces of neodymium boron, or by melting a piece of ndferrocodong, or by melting the two together, through a process called plating. NdFeB magnets possess several distinct physical characteristics. While being one of the few metals that possesses this versatile feature, it is also one of the most difficult to form, and it is most commonly found as a solid metal that is difficult to work with, and which produces the highest levels of hardness. NdFeB magnets are also extremely strong, with a tensile strength greater than 10 times that of sodium, one of the stronger alloys. Because of these unusual physical properties of the NdFeB magnet, these magnets are often used for applications requiring extreme strength, hardness, and wear resistance.

Another unique property of NdFeB magnet is its electro-statically charge retaining property, which enables this particular type of magnet to have two-sided attraction or repulsion between opposite sides of a bar. This property allows NdFeB magnets to be used in a variety of mechanical applications, including friction and wear plates. As a result, a mechanical property known as electro-statically induced magnetization (EMT) is achieved in this material, where two poles repel and attract each other. The reason why two poles attract is due to the fact that the attraction/repellance occurs at a fraction of a degree of change in the alignment of the particles, which results in a net movement of kinetic energy.

An additional, related, physical property of NdFeB magnet is its magnetic field. The NdFeB magnet possesses a unique, nearly unbreakable magnetic field, which is stronger than that of almost all naturally occurring elements. The strength of the NdFeB magnetic field is measured in gauss units and is measured as a distinct, nontoxic component in natural materials. A nonmagnetic metal may be used as an electrode in some of the processes involving the generation of electrical current, such as those used in the manufacture of electric cars. However, using a nontoxic metal as an electrode does not alter the physical properties of the material, and can produce the same effect.

Although it was not known at the time that NdFeB magnets had such unique characteristics, recent research has uncovered several new applications for these special magnets. Several unique features of NdFeB magnets have enabled them to make a number of promising new applications in the field of magnetism. First, they have an overall higher electrical conductivity than most of the other natural magnetic metals. They also have a far higher intrinsic strength than any of the other known materials. Finally, they have a far higher frequency than any of the other materials. These properties make NdFeB a very attractive choice for use in many new applications.

One of the many interesting new applications for NdFeB magnets is their potential as energy generation devices. NdFeB magnets produce an electron spin current that can be used to power a number of electrical devices, including portable generators. For this reason, this type of magnet may prove to be very useful as a renewable source of alternative energy. Because the electron spin current produced by this rare earth magnet is unique, and more importantly, nontoxic, there are no health risks associated with its use as an alternative energy source.

NDFeb is a composition of ferricyanide and ferric oxide, along with other commonly used elements. The unique characteristic of the NdFeB magnet makes it ideal for use in a number of unique applications. In fact, this material has been extensively studied for its special magnetic properties and is widely used in a variety of industries. NDFeb magnetic motors use NdFeB magnets as the main component in their construction, which allows them to be used for a wide range of applications. They are largely used in the aerospace industry to power various control and navigation instruments used on commercial and passenger aircraft.

sales00@jlmagnet.com

sales00@jlmagnet.com