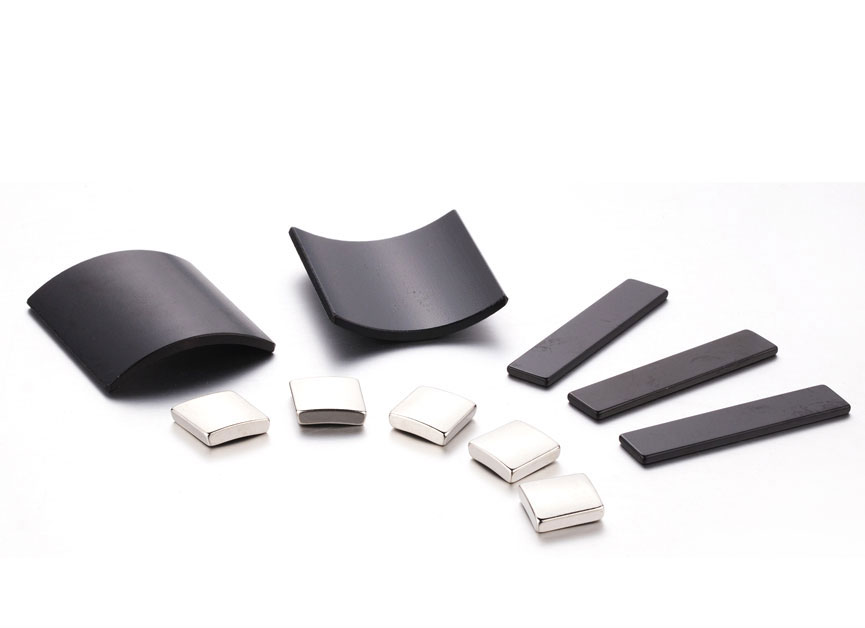

NdFeB pressure type

After the powder is oriented in a magnetic field, a mold is used to form a blank with a certain dimensional tolerance, and the process of further densification by isostatic pressing is called forming. The process is that the powder is weighed according to the weight of the required blank under the protection of nitrogen, and then poured into the mold cavity. The electrodes placed on both sides of the mold are energized to generate a magnetic field, so that the powder particles in the mold cavity rotate along the magnetization direction. The poles are kept in the same direction. At this time, the upper and lower pressure heads are pressurized in opposite directions. After reaching a certain density, the vacuum package is taken out, and then placed in the isostatic pressure. The hydraulic oil in the closed container is pressurized and the hydraulic oil is used as the medium. The pressure is evenly transmitted to the blank, so that it is fully stressed and compacted again to reach the required density, creating conditions for the next step of sintering and improving its oxidation resistance.

At present, there are three types of molding methods commonly used: membrane pressure, mold pressing and cold isostatic pressing and rubber mold isostatic pressing. With the same neodymium content, rubber mold isostatic pressing can obtain a larger magnetic energy product.

NdFeB orientation

Magnetic materials are divided into two types: isotropic magnets and anisotropic magnets. Isotropic magnets have the same magnetic properties in any direction and can be attracted together at will; anisotropic magnets have different magnetic properties in different directions, and the direction that can obtain the best magnetic properties is called the orientation direction of the magnet. For a square sintered NdFeB magnet, only the orientation direction has the highest magnetic field strength, and the other two directions are much smaller.

Sintered NdFeB magnets are generally molded and pressed by magnetic field orientation, so it is anisotropic. Therefore, it is necessary to determine the orientation direction before production, the upcoming magnetization direction. Powder magnetic field orientation is one of the key technologies for manufacturing high-performance NdFeB magnets. One.

sales00@jlmagnet.com

sales00@jlmagnet.com