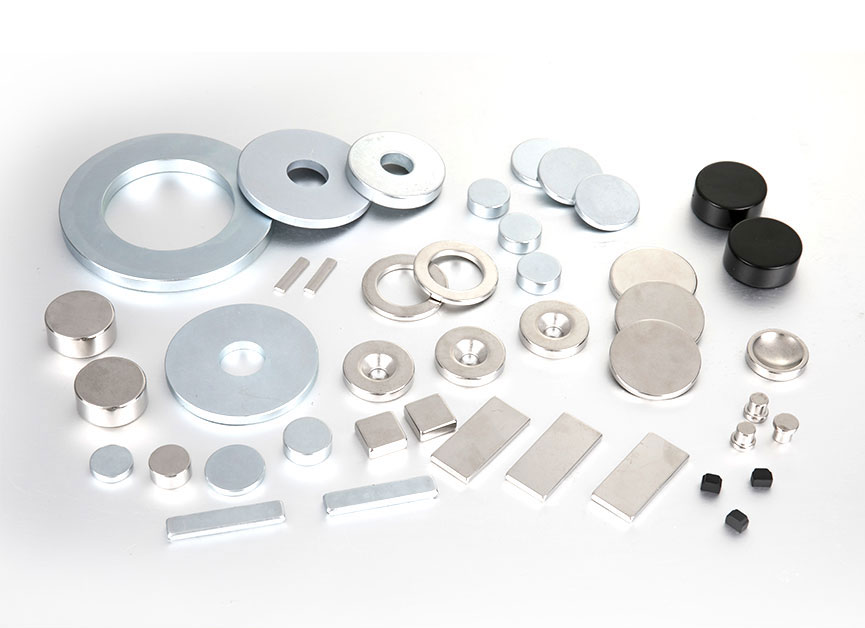

Neodymium Disc Magnets is round, coin shaped Neodymium Magnets of varying thickness and diameter. Neodymium is a precious metal that is nearly as hard as steel. Typically, Neodymium Magnets have been fabricated and used for more than one hundred years.

Generally, Neodymium Disc Magnets is more commonly used in industrial applications where a bearing must be shielded from the effects of friction, excessive heat, and an atmosphere which can affect the quality and life of the bearing. In a way, Neodymium Magnets is somewhat similar to air gap magnets. However, because they are usually placed in environments that are heavily loaded with air, the magnets tend not to be affected by high levels of humidity and static electricity. These are the best suited for use where the magnet will be working and potentially causing friction and damage to other parts of the bearing.

Unlike other neodymium disc magnets, NdFeB magnet models are made in a three layer design. The first layer is made of purely nickel alloys and the center layer is made of a thin layer of boron. Because nickel is such a good conductor of electricity, it allows the third layer a larger conductivity band. The result is that the third layer provides more energy to the magnetic field and therefore allows the field to be stronger. Neodymium has unique properties compared to other alloys - including its ability to provide a much higher current capacity per unit area.

The other thing that gives Neodymium Disc Magnets an edge over other materials is their thickness. Neodymium is a very thick metal. It's about double the thickness of stainless steel. While this doesn't mean much on its own, it means that Neodymium Disc Magnets tends to be stronger and more durable than their less expensive counterparts.

The reason that Neodymium Disc Magnets tends to be a little more robust and reliable than other similar materials comes from the second feature that a thin layer of nickel offers. The nickel alloys used in the construction process to allow Neodymium to have a much bigger diameter than other metals. This allows for stronger magnetic fields and larger pulls on the Neodymium Magnets. Because of the way that Neodymium is thicker than the other materials that magnets are typically made out of (Nickel alloys), the end result is a much bigger diameter and greater pull force.

Additionally, there is the fact that Neodymium tends to be slightly toxic to humans and other living things. When Neodymium is created with nickel alloys, the alloy has a small air gap between the metal and the neodymium disc. This air gap allows for the Neodymium to be much more corrosion resistant. The nickel alloys in Neodymium Disc Magnets are also somewhat inert. This means that the Neodymium can sit on top of the magnets without attracting any of the corrosive properties of the metal.

Neodymium is a very popular choice for manufacturers because of the fact that it tends to be very stable. Jinlun is professional China Neodymium Disc Magnets manufacturer and supplier. The quality of Neodymium that is available tends to be better than stainless steel. Neodymium is also used in the construction of large magnets such as the ones you see at science stores. Although the grade of Neodymium that you will find tends to be stronger than that grade of stainless steel, the magnets made out of Neodymium still tend to be a little bit malleable. For this reason, manufacturers tend to use slightly less Neodymium in the Large Magnets that they make than they would have if they had used higher grade Neodymium. As a result, Neodymium Large Magnets tends to pull harder on the alignment bars than would be expected from using higher grade material.

Neodymium tends to be a very flexible metal that is frequently used for a variety of different applications. In addition to being used in large industrial products such as large industrial counter-tops and plates, the Neodymium that is used for the counter-tops and plates tend to be more durable than the more affordable grades of Neodymium. For this reason, it is very important that when choosing Neodymium you look for high quality Neodymium with the appropriate coating.

sales00@jlmagnet.com

sales00@jlmagnet.com