Neodymium is a rare metallic material that has recently found its way into modern technology due to its unique electro-magnetic properties. These properties are particularly attractive to the field of magnetism, where they have myriad applications. Neodymium is formed from a mixture of two metals - neodymium and magnetite - with each forming a small number of magnet atoms. Unlike many other forms of magnetism, this type of magnetic metal is strongly attracted to strong north and south magnetic fields, but repelled towards a weaker magnetic field. As a result, neodymium is often used in applications requiring a large amount of power (i.e., it's used for rocket motors and sailboats).

Neodymium Magnet grade A: Neodymium is one of the strongest magnetic fields observed in nature, and so is a good choice for high-powered applications requiring a large amount of electrical current, such as in rocket motors and sailboats. However, because it is so powerful in its natural form, these magnets are also extremely heavy, making them unsuitable for use in many applications where smaller, lighter materials would be preferable. Neodymium Magnet grade B: Neodymium is now frequently combined with iron to produce a stronger alloy that is more suitable for use in applications requiring a higher current. Neodymium Magnet grade C: This is the strongest magnet material and most widely used in industrial applications. It is a mixture of magnetite and neodymium to create a metal that is extremely responsive to both north and south magnetic fields.

Because of its electro-magnetic properties, a neodymium magnet is often combined with other elements. For instance, graphite and steel are often combined with neodymium to create a permanent magnetic structure. The resulting creation of permanent magnets is referred to as "ferromagnetism." This is different from electromagnetic induction, which involves an outside source driving an electric field through a conducting material. The process of creating permanent magnets does not include the attraction-repulsion characteristic of electromagnetic induction, but rather involves the mutual repulsion of magnets. Thus, permanent magnets can have a much greater pull on a weight than an electromagnetic induction machine.

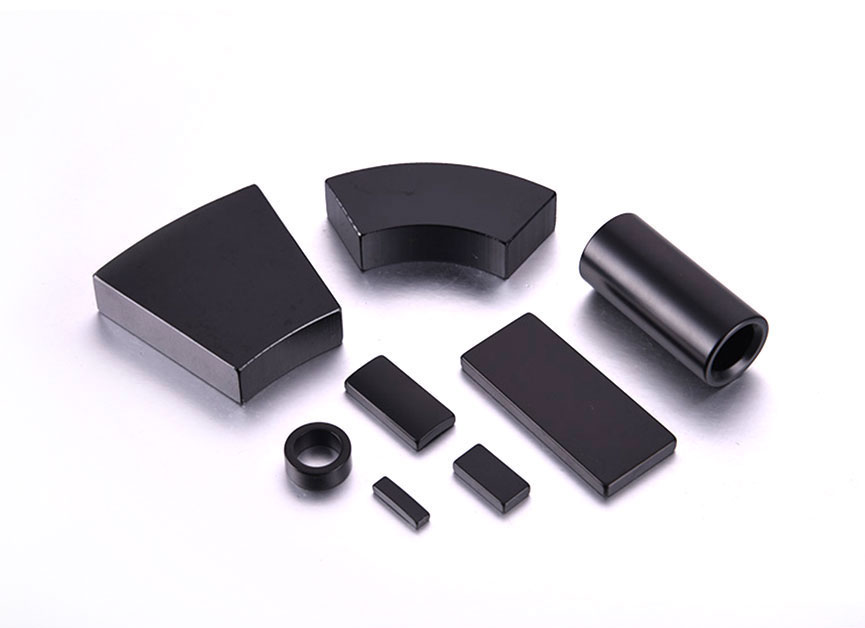

Neodymium Magnets is usually manufactured as a thin film of ndfeb alloy. The flat, nearly sheet-like surface is generally referred to as "dipstick" because it is used as a component for custom packaging. Neodymium Magnet suppliers can then package Neodymium Magnet products for sale in attractive looking finishes such as "hot pink," "rust," or "galvanized finish." These finishes can provide an attractive alternative to traditional metallic packing materials. Because the Neodymium Magnet is dipstick-like in appearance, the custom packaging applications are even more attractive and can be utilized for many different applications.

The most popular use for a Neodymium Magnet is in the manufacture of high quality electrical components such as motor wirings, solar power cells, cell phones, laptop computers, and other small electronic devices. The Neodymium Magnet is made of two independent crystals that form a strong magnetic field when electrically charged. Because the Neodymium Magnet consists of two independent crystals, the manufacturing process provides a higher performance than most common raw materials and processes. As a result, the Neodymium Magnet is able to maintain an exceptionally high electrical current despite its small size.

The unique properties of neodymium magnets make them unique in many ways. One of these unique features is their ability to retain an exceptionally high level of charge, which is necessary for creating new applications for consumer products and electrical equipment. The Neodymium Magnet can maintain more than 1000 Gauss units, or force, of force, which is ten times greater than most common materials used for this type of strength rating. This allows for larger Neodymium Magnets to be used in new applications where larger force levels are required, including industrial and medical applications.

The Neodymium Magnet can be used to build Neodymium Wire, which is a very useful construction material for constructing large-scale products and industries. Neodymium Wire is commonly used to construct high-length wires that are required in military applications, because these wires are capable of sustaining enormous amounts of force without damaging the material they are constructed of. For this reason, the Neodymium Magnet is ideal for constructing aircraft engines, generators, rocket motors, and other extremely large industrial machines. They also work well for high-weight, long-lasting cable ties, because these ties are often subjected to tremendous force and stress and need to have extremely tough, flexible backs to prevent separation and decomposition.

Neodymium Magnets are the only materials that produce stable, nearly electromagnetic fields that can be manipulated by the human body. This feature makes them ideal for use as an alternative to the more common forms of ESD therapy. In addition, because the Neodymium Magnets work using only one polarity, they are completely safe for use even in medical settings, where the FDA has approved the use of only one polarity materials for safety purposes. You can easily buy from Neodymium Magnets manufacturers and factory in China. As Neodymium Magnets continues to gain popularity as an alternative therapy for electromagnetic fields, they will undoubtedly replace stronger, more hazardous forms of ESD therapy in the years to come.

sales00@jlmagnet.com

sales00@jlmagnet.com