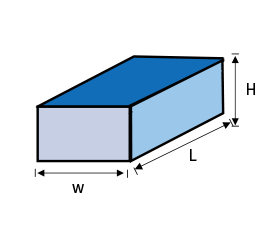

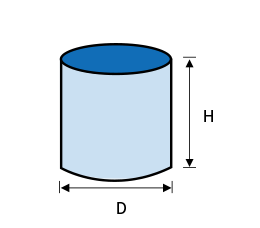

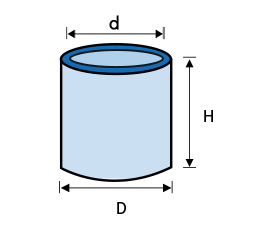

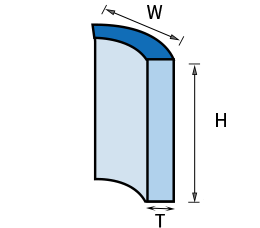

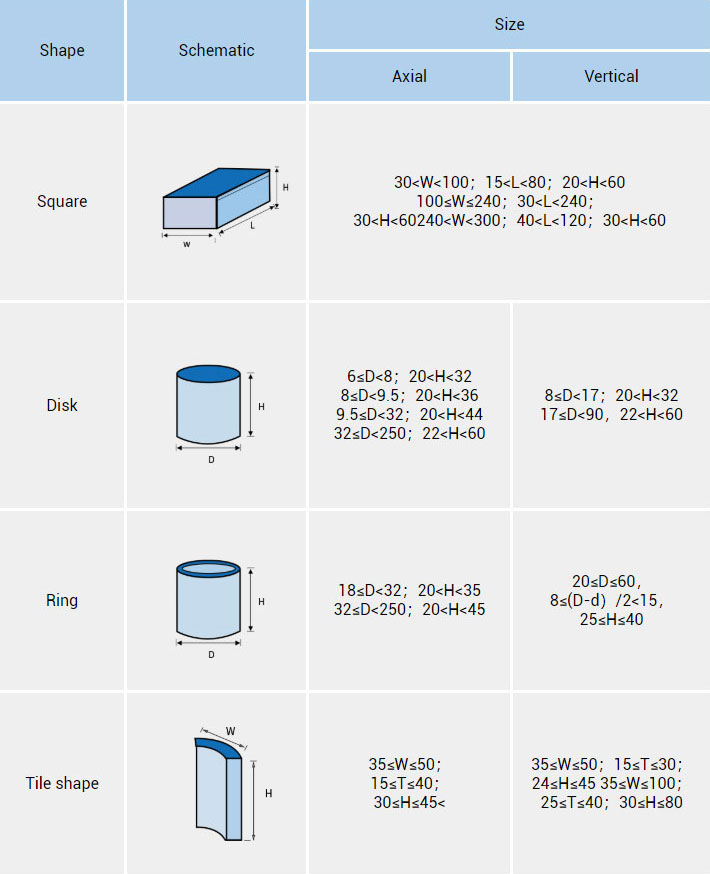

| Shape | Schematic | Size | |

| Axial | Vertical | ||

| Square |  |

30<W<100;15<L<80;20<H<60

|

|

| Disk |  |

6≤D<8;20<H<32

|

8≤D<17;20<H<32 |

| Ring |  |

18≤D<32;20<H<35

|

20≤D≤60, |

| Arc |  |

35≤W≤50;

|

35≤W≤50;15≤T≤30;24≤H≤45 |

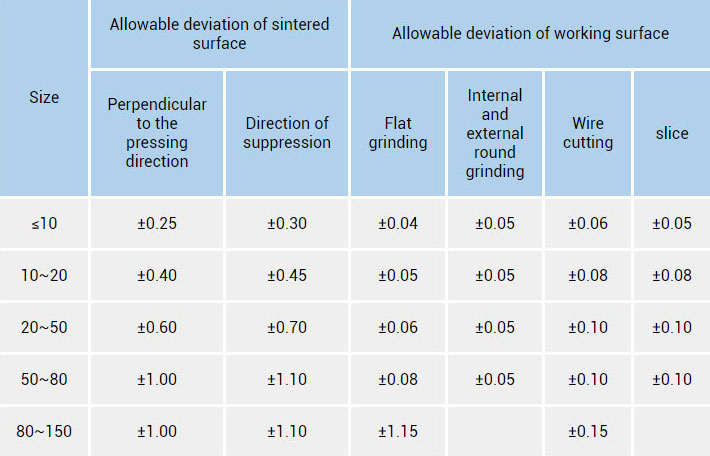

| Size | Allowable deviation of sintered surface |

Allowable deviation of working surface |

||||

| Perpendicular to the pressing direction | Direction of suppression | Flat grinding | Internal and external round grinding | Wire cutting | slice | |

| ≤10 | ±0.25 | ±0.30 | ±0.04 | ±0.05 | ±0.06 | ±0.05 |

| 10~20 | ±0.40 | ±0.45 | ±0.05 | ±0.05 | ±0.08 | ±0.08 |

| 20~50 | ±0.60 | ±0.70 | ±0.06 | ±0.05 | ±0.10 | ±0.10 |

| 50~80 | ±1.00 | ±1.10 | ±0.08 | ±0.05 | ±0.10 | ±0.10 |

| 80~150 | ±1.00 | ±1.10 | ±1.15 | ±0.15 | ||

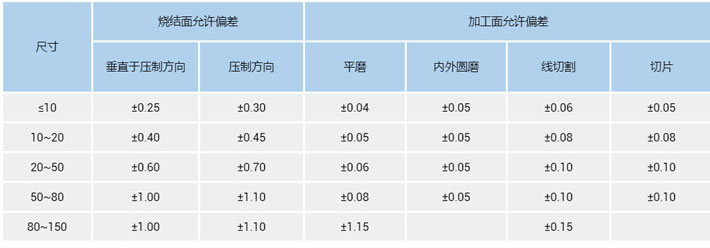

| Variation type | Variation type | Basic size(mm) | Deviation | |

| Parallelism | Working surface room |

One half of the tolerance value between the two planes |

||

| Verticality | Between sintered surfaces | Random | 90°±1° | |

| Between machined surface and sintered surface | 90°±1° | |||

| Working surface room | 90°±0.15° | |||

| Concentricity | Between sintered surfaces | Outer diameter | ≤14 | ±0.35mm |

| 14~24 | ±0.60mm | |||

| 24~40 | ±0.80mm | |||

| 40~60 | ±1.100mm | |||

| 60~80 | ±1.150mm | |||

| 80~180 | ±2.00mm | |||

| Working surface room | Random | ±0.08mm | ||

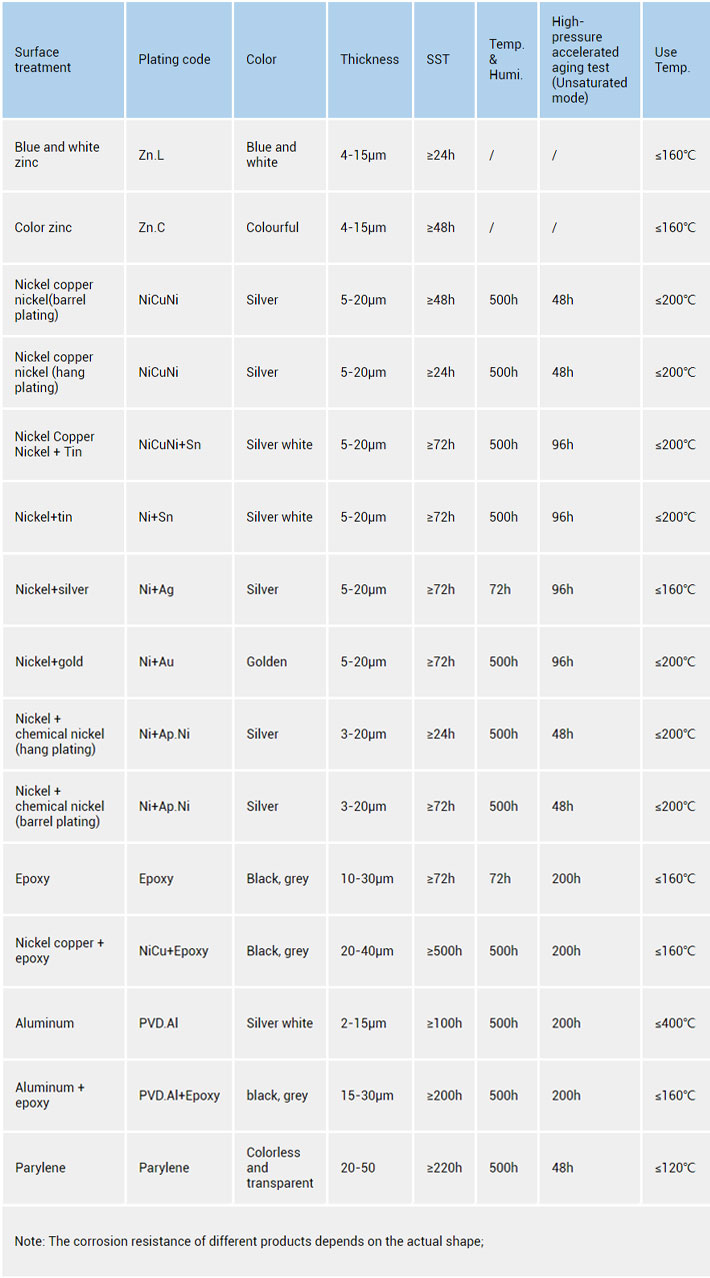

| Surface treatment | Plating code | Color | Thickness | SST | Temp. & Humi. | High-pressure accelerated aging test (Unsaturated mode) |

Use Temp. |

| Blue and white zinc | Zn.L | Blue and white | 4-15μm | ≥24h | / | / | ≤160℃ |

| Color zinc | Zn.C | Colourful | 4-15μm | ≥48h | / | / | ≤160℃ |

| Nickel copper nickel(barrel plating) | NiCuNi | Silver | 5-20μm | ≥48h | 500h | 48h | ≤200℃ |

| Nickel copper nickel (hang plating) | NiCuNi | Silver | 5-20μm | ≥24h | 500h | 48h | ≤200℃ |

| Nickel Copper Nickel + Tin | NiCuNi+Sn | Silver white | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel+tin | Ni+Sn | Silver white | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel+silver | Ni+Ag | Silver | 5-20μm | ≥72h | 72h | 96h | ≤160℃ |

| Nickel+gold | Ni+Au | Golden | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel + chemical nickel (hang plating) | Ni+Ap.Ni | Silver | 3-20μm | ≥24h | 500h | 48h | ≤200℃ |

| Nickel + chemical nickel (barrel plating) | Ni+Ap.Ni | Silver | 3-20μm | ≥72h | 500h | 48h | ≤200℃ |

| Epoxy | Epoxy | Black, grey | 10-30μm | ≥72h | 72h | 200h | ≤160℃ |

| Nickel copper + epoxy | NiCu+Epoxy | Black, grey | 20-40μm | ≥500h | 500h | 200h | ≤160℃ |

| Aluminum | PVD.Al | Silver white | 2-15μm | ≥100h | 500h | 200h | ≤400℃ |

| Aluminum + epoxy | PVD.Al+Epoxy | black, grey | 15-30μm | ≥200h | 500h | 200h | ≤160℃ |

| Parylene | Parylene | Colorless and transparent | 20-50 | ≥220h | 500h | 48h | ≤120℃ |

| Note: The corrosion resistance of different products depends on the actual shape; | |||||||

Please complete the form below and one of our team will get back to you as soon as possible.